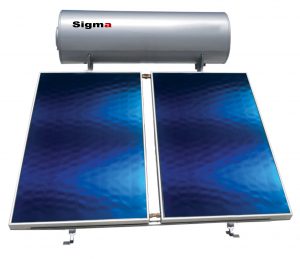

Typical boiler system

Typical Boiler systems

Typical boiler systems are the most widespread systems in Southern European and African countries, as high temperatures are not a limiting factor as to where the boiler is placed, which is not the case in Central and Northern European countries. This system consists of the collector, the boiler and the support base.

Safe use of clean water

The inside of the boiler is enameled with an inert material – a mixture of inorganic silicates – without chemical additives. The high firing temperature of 850ºC has formed a glassy surface, so that the water inside the boiler is so clean that, apart from being used for bathing, it can even be used for domestic purposes. Absolutely safe for health, because it does not allow the growth of bacteria according to DIN 4753 Teil 3 & 6. The enamelling process is certified with the enamel quality mark (DEV).

Regional exchanger for maximum performance

Because the solar water heater operates without forced circulation (circulator), Sigma’s boiler uses a jacket-type exchanger (rather than a serpentine) for maximum efficiency, which surrounds most of the tank.

Strong polyurethane insulation

Hot water , thanks to the strong 50 mm polyurethane insulation, which surrounds the entire tank, without chlorocarbon. Polyurethane injection with a special mixing machine for a perfect result.

Lifetime

Due to the special low-carbon steel, the coating, the anodised aluminium foil outer casing and the technical expertise of our company, Sigma Energy guarantees you a long life of the tank. Even under the most adverse weather conditions that a solar water heater, installed outdoors, can face, Sigma Energy’s boiler has a lifetime, one of the longest in the European market.

| Enclosure | Prepainted Galvanized Steel 0.6mm, color RAL 9006 |

| Insulation | Polyurethane without C.F.C., p=40kg/m², thickness 50mm |

| Boiler thickness ( mm ) | 2,5 |

| Boiler protection | 850º C with direct coating |

| Operating pressure ( Bar ) | 10 |

| Dimensions ( mm ) | Φ520 x 1290 |

| Jacket capacity in liquid ( L ) | 4,0 |

| Weight ( kg ) | 48 |

| Enclosure | Prepainted Galvanized Steel 0.6mm, color RAL 9006 |

| Insulation | Polyurethane without C.F.C., p=40kg/m², thickness 50mm |

| Boiler thickness ( mm ) | 2,5 |

| Boiler protection | 850º C with direct coating |

| Operating pressure ( Bar ) | 10 |

| Dimensions ( mm ) | Φ520 x 1290 |

| Jacket capacity in liquid ( L ) | 4,6 |

| Weight ( kg ) | 57 |

| Enclosure | Prepainted Galvanized Steel 0.6mm, color RAL 9006 |

| Μόνωση | Polyurethane without C.F.C., p=40kg/m², thickness 50mm |

| Boiler thickness ( mm ) | 2,5 |

| Boiler protection | 850º C with direct coating |

| Operating pressure ( Bar ) | 10 |

| Dimensions ( mm ) | Φ580 x 1290 |

| Jacket capacity in liquid ( L ) | 4,9 |

| Weight ( kg ) | 65 |

| Enclosure | Prepainted Galvanized Steel 0.6mm, color RAL 9006 |

| Insulation | Polyurethane without C.F.C., p=40kg/m², thickness 50mm |

| Boiler thickness ( mm ) | 2,5 |

| Boiler protection | 850º C with direct coating |

| Operating pressure ( Bar ) | 10 |

| Dimensions ( mm ) | Φ520 x 1690 |

| Jacket capacity in liquid ( L ) | 5,8 |

| Weight ( kg ) | 90 |